Temp Range: 90° - 135° F / Space Heating Size: Up to 6,300 Sq. Ft.

Tubing In Concrete Emitters

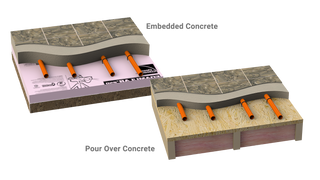

One of the easiest and most cost efficient ways to install hydronic radiant heat is to use the tubing in concrete method. The two different methods are Embedded Concrete and Pour Over.

With Embedded Concrete, you install a vapor barrier over the compacted fill, then place foam insulation. Use only oxygen barrier tubing and secure with staples. Concrete is poured over top and then you can place the flooring of your choice.

Pour Over can be installed over a subfloor and secured down before pouring over the cement. Then place the flooring of your choice.

When sizing boiler, Multiply 30 BTU/Sq. Ft. Hr. by total sq. ft. Example: 1200 Sq. Ft. x 30 BTU = 36,000. Your BTU requirements for 1200 Sq. Ft. would be 36,000 BTU, with good insulation quality.

Tubing in Concrete Emitters can be used with all of our Low & High Temp Gas or Electric Boilers

Benefits of Tubing In Concrete

Comfortable

Radiant heat warms the floor, which warms your feet and makes you feel more comfortable.You can feel comfortable walking on the floor barefoot, even in winter.

Efficient

Radiant heat is more efficient than forced-air systems because it minimizes heat loss and uses energy more effectively.

Noise Reduction

Radiant heat systems are quiet, unlike forced-air systems that can be noisy.

Healthy

Radiant heat is healthier than forced-air systems because it doesn't circulate dust and allergens through the air.

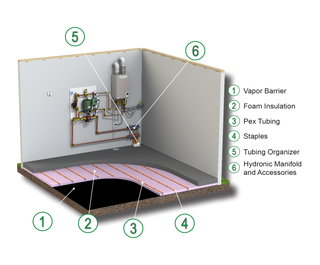

Tubing in Concrete Components

A vapor barrier is essential as it provides vapor/moisture barrier to help prevent water from coming up from the ground to the concrete.

Insulation is critical. Use 2” of high pressure rated extruded polystyrene under the slab, and around perimeter. Do not use bubble type or faced insulation.

Use only oxygen barrier tubing for a radiant heating system. Spacing for 1/2” tubing is 9-12" on center with a maximum sidewall height of 12 ft. You should have a minimum of R19 wall insulation, R38 ceiling insulation with 2" of extruded styrene insulation under and around the slab. 300’ is the maximum length to avoid too much drop in the water temperature from the beginning to the end of the loop. For zones over 3500 sq. ft. or sidewalls higher than 12 ft., please call Hydro Smart at 1-800-446-2070.