Boiler & Panel Systems Overview

For clean, comfortable and economic heat, choose a Hydro Smart Radiant Heating System

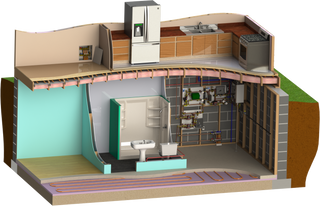

The Hydro Smart panel systems operate on a principal of hydraulic separation between the Boiler circuit and the Emitter circuit (tubing, baseboard etc.). This hydraulic seperation creates the ability to adjust the flow in the Boiler circuit independently from the Emitter circuit while still passing heat from the Boiler to the Emitters. Flow rate for boilers and emitters need be adjusted for optimal heat output performance.

System Considerations

1.

What type of Emitter(s) do you have?

2.

How many square feet will you be heating?

3.

How many thermostat zones will you have?

4.

Are you going to heat with a Electric or Gas boiler?

Step 1

Choose Emitter Type:

In order for emitters to get their proper BTU output the fluid delivery temperature needs to be considered before selecting your boiler.

Step 2

Boiler options are available in both Electric and Gas options. Boilers have different BTU Outputs and water delivery temperatures.

Gas Boilers

LP or NG Options

You can choose from condensing

or non-condensing options.

Condensing Boilers operate at 94% or more and require a floor drain and use PVC venting. Non-Condensing Boilers operate at 84% and do not require a floor drain and use Stainless Steel Cat. lll venting.

LOW TEMP

HS115Plus Gas Boiler

• NG w/ LP Conversion Kit

• Non-Condensing

• Temp Range: 99° - 140° F

• 4” Cat III SS Venting

• BTU Output: 16,000 - 114,800

• Space Heating: 900 - 3500 Sq. Ft.

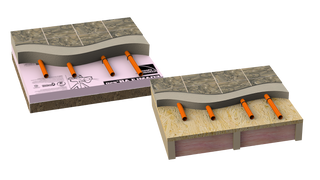

• Emitters: Tubing in Concrete

LOW TEMP

HS120Plus Gas Boiler

• NG or LP Models

• Condensing: Floor Drain Req.

• Temp Range: 99° - 140° F

• 3” Schedule C PVC (solid core)

• BTU Output: 13,950 - 111,600

• Space Heating: 900 - 3500 Sq. Ft.

• Emitters: Tubing in Concrete

HIGH TEMP

HS199 Gas Boiler

• NG or LP Models

• Condensing: Floor Drain Req.

• Temp Range: 80° - 185° F

• 3” Schedule C PVC (solid core)

• BTU Output: 12,350 - 189,050

• Space Heating: 900 - 5000 Sq. Ft.

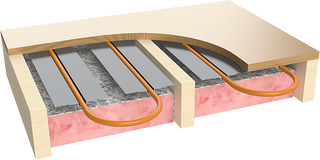

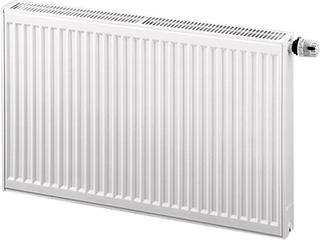

• Emitters: Tubing in Concrete, Staple Up,

Fan/Coil, Radiators, Baseboard

Electric Boilers

Service size is the biggest consideration

The KW of the boiler dictates amperage draw on the system. It is necessary to make sure your boiler works with your electrical service size. See your boiler brochure for detailed specs on each model.

Hydro Shark Electric Boilers

• 7 - 36 kW Models

• Temp Range: 86° - 140° F

• No Venting Needed

• BTU Output: 24,537 - 122,868

• Space Heating: 300 - 3500 Sq. Ft.

• Emitters: Tubing in Concrete

Thermo 2000 Electric Boilers

• 3 - 33 kW Models

• Temp Range: 50° - 190° F

• No Venting Needed

• BTU Output: 10,236 - 122,832

• Space Heating: 100- 3300 Sq. Ft.

• Emitters: Tubing in Concrete, Staple Up,

Fan/Coil, Radiators, Baseboard

Step 3

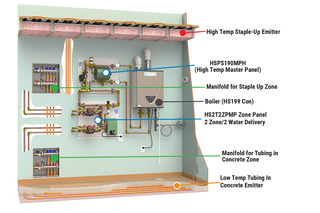

Choose a Compatible Panel and Zoning Panel (if needed)

Your panel selections will be based off a number of factors. Your Emitter(s) and Boiler will determine which panel(s) you will need. Your panel selection will also be based off of your number of zones. If you have 1 Zone, you will only have 1 Panel. If you have multiple zones, you will need two panels. (An Integrator (Master) Panel and a Zone Panel). Refer to the Emitter Pages for panel and zoning selection to help determine your panel(s).

The Hydro Smart panel systems operate on a principal of hydraulic separation between the Boiler circuit and the Emitter circuit (tubing, baseboard etc.). This hydraulic separation creates the ability to adjust the flow in the Boiler circuit independently from the Emitter circuit while still passing heat from the Boiler to the Emitters. Flow rate for boilers and emitters need be adjusted for optimal heat output performance.